Sacks & Bags

Industries Served

Sacks & Bags

Industries Served

Sacks & Bags

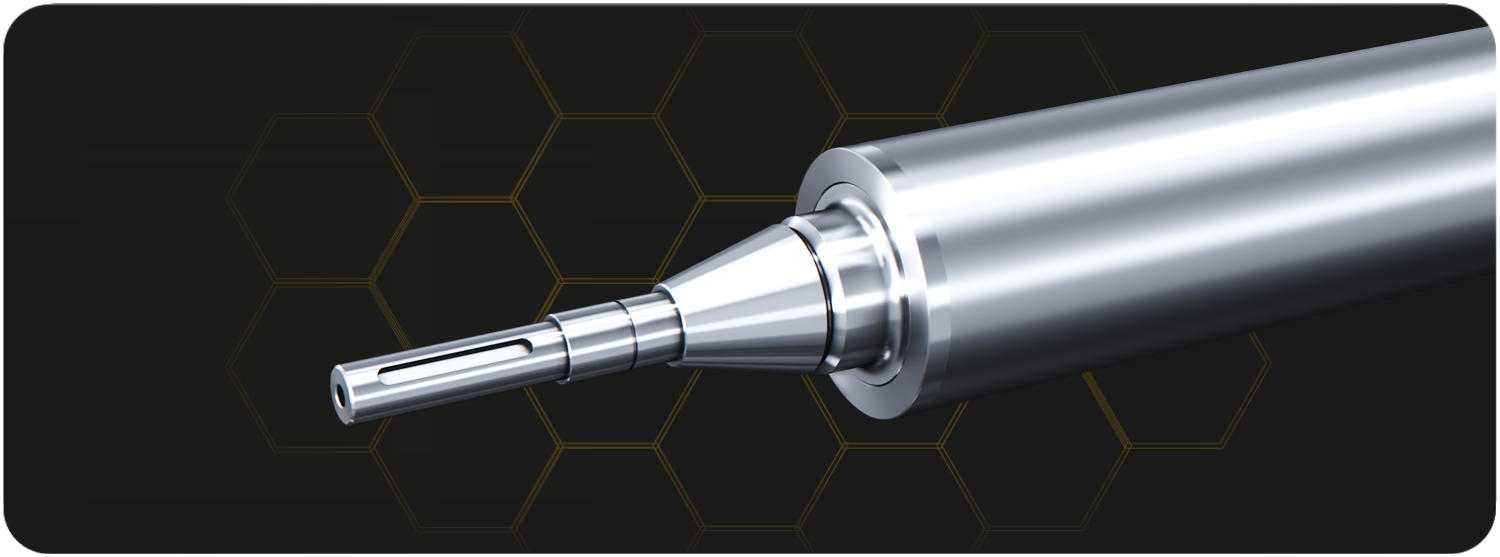

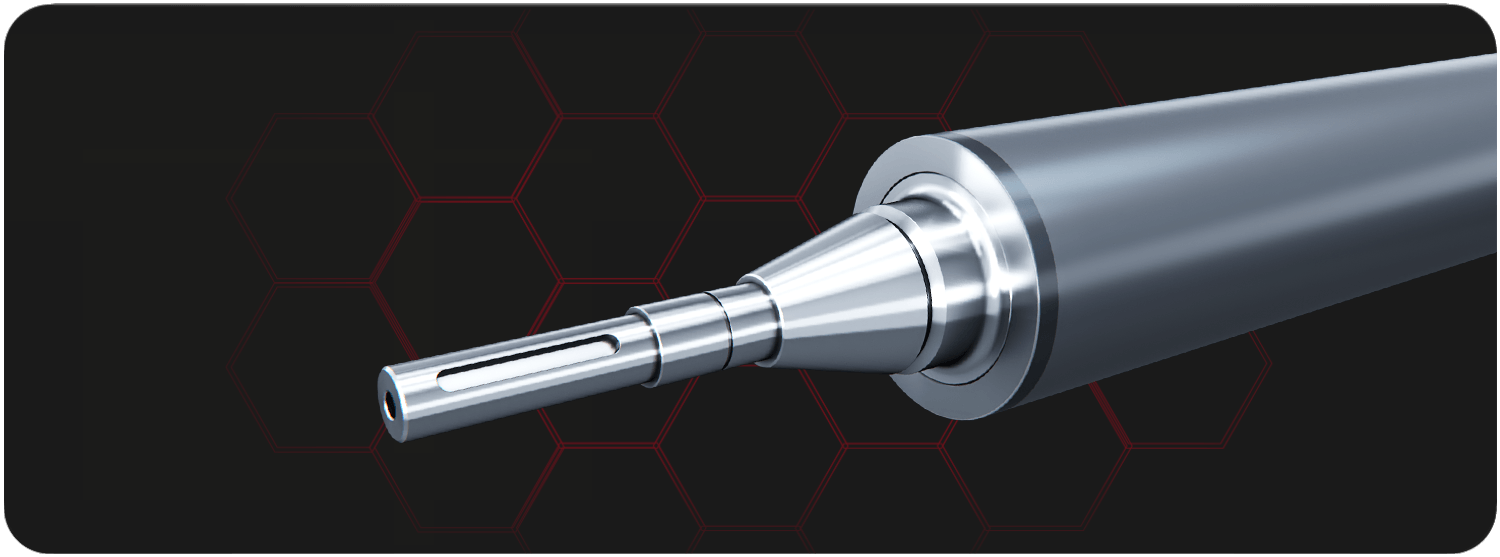

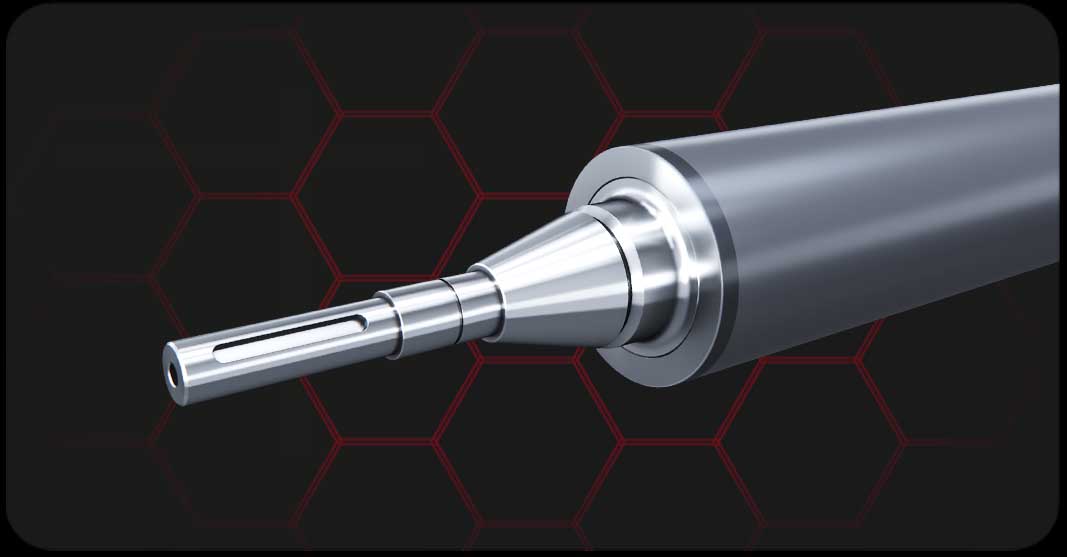

To the printers of paper sacks and bags we offer rollers engraved into steel or galvanic nickel with different cell types and screens up to 220 l/cm, engineered to avoid side damages typical of three-roll inking. In addition to traditional pyramidal and truncated-pyramid engravings, we have developed geometries similar to those proposed for laser engravings into ceramic that guarantee better ink release and high definition printing.

To the printers of paper sacks and bags we offer rollers engraved into steel or galvanic nickel with different cell types and screens up to 220 l/cm, engineered to avoid side damages typical of three-roll inking.

Select the anilox range you are interested in

DELTOR for Sacks & Bags

We rely on production lines and tools dedicated to this application. In addition to the traditional configurations, we have developed geometries that replicate those used for laser engraving into ceramics, thus optimizing the performances of each system. The technology at our disposal allows us to detect and reproduce every geometry. We engrave on different substrates to get greater resistance and preserve the cylinders from lateral damage typical of the three-roll inking.

Engraving

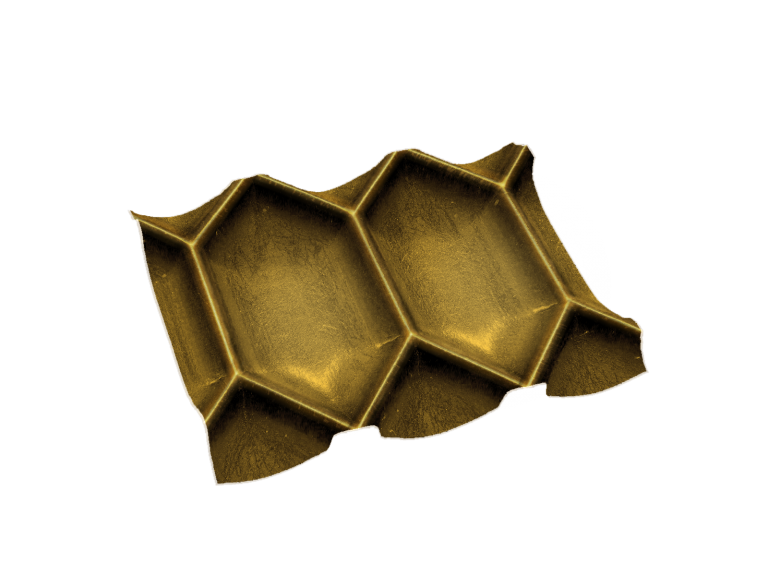

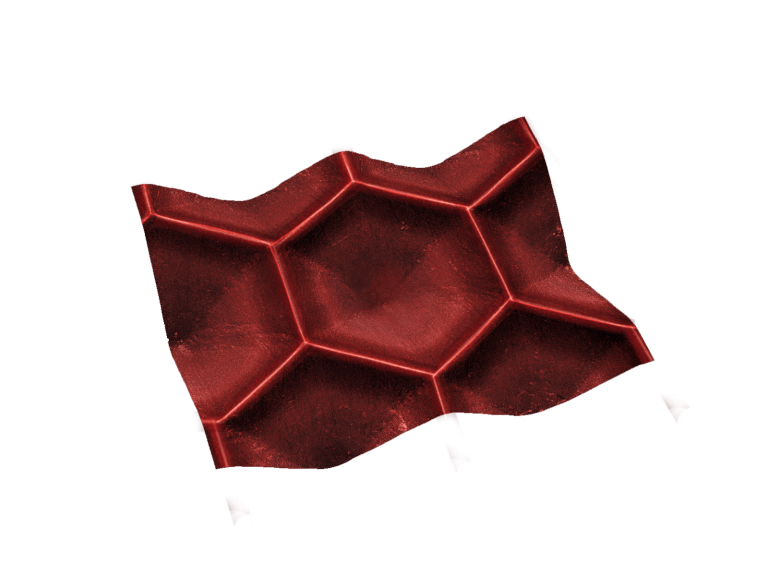

Double cell

Engraving

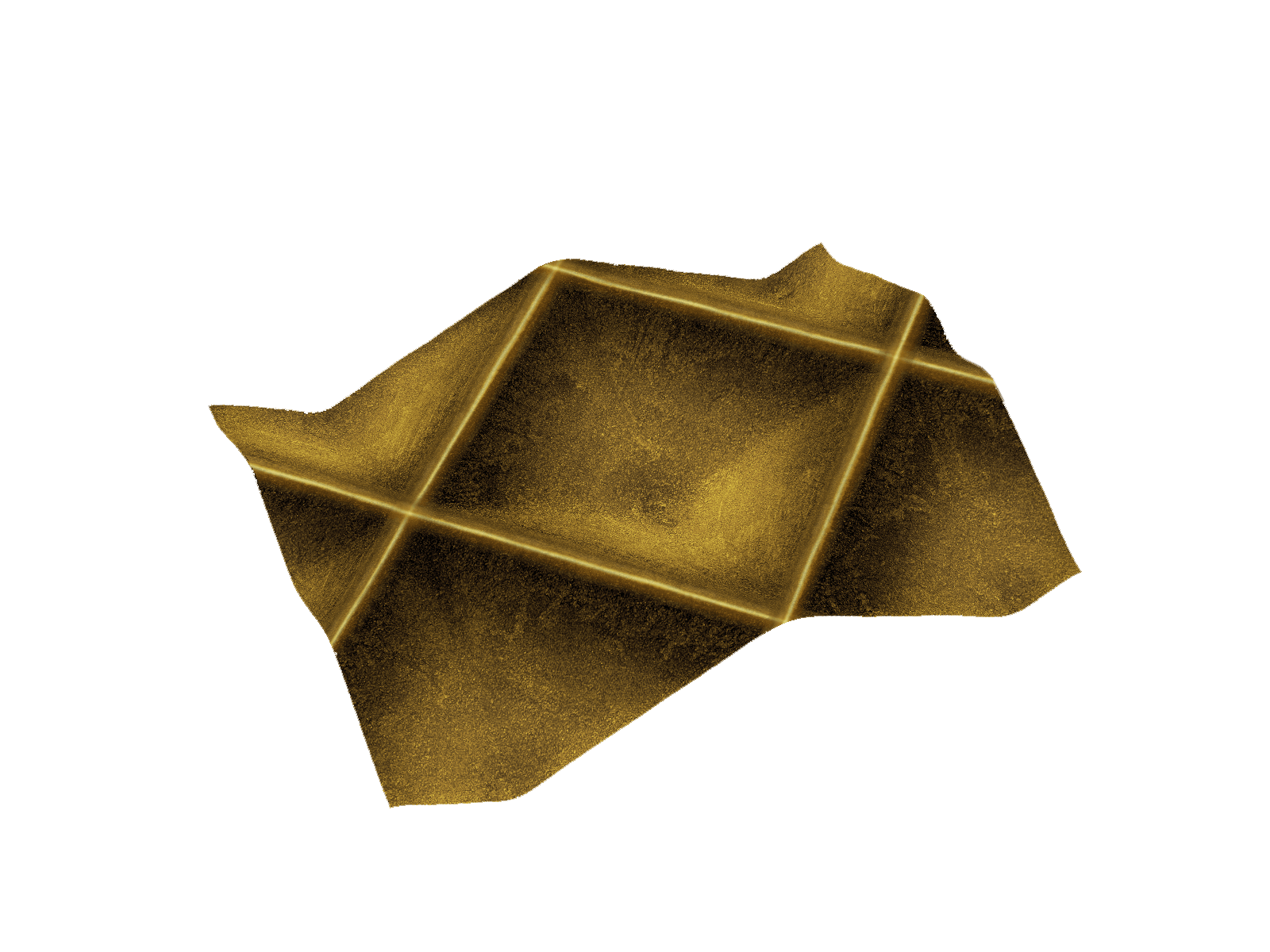

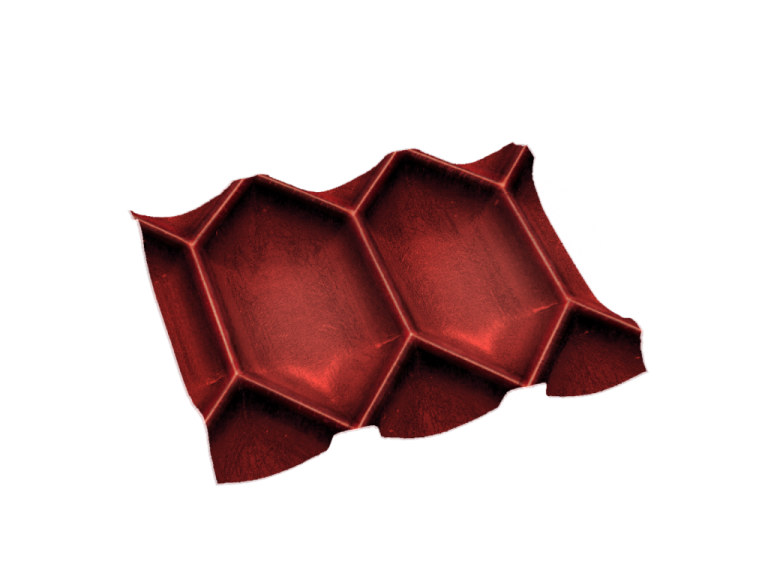

Pyramidal

Engraving

Truncated Pyramid

Substrates

We offer a wide range of deposition technologies, including galvanic coatings such as chrome, nickel and copper; welding coatings such as carbon-steel, stainless steel and alloys; and thermal spray coatings such as wire copper or other materials.

STEEL

COPPER

NICKEL

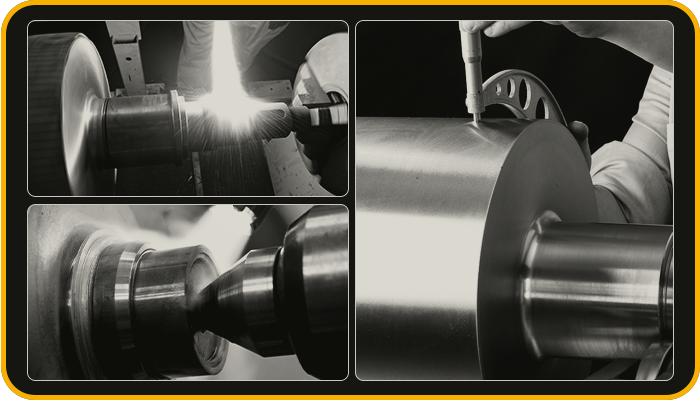

REFURBISHMENT

Our procedures ensure that a refurbished roller has the same performance and operating life as a new one. All machining operations follow the OEM specifications recorded in our database. Each anilox has an ID card where all significant steps in its life cycle are recorded, allowing us to analyse its performance over time.

DIAMETER REBUILDING

The refurbishment of mechanically engraved chromed rollers implies the roller diameter reduction. If required by OEMs' manufacturing specifications, we restore the diameter and apply a substrate selected among nickel, copper or steel depending on the model and on the requirements of the machine on which the roll will be installed.

Purchasing Options

STARLOX for Sacks & Bags

A coating developed to meet the needs of this industry and applied by plasma or submerged arc welding provides excellent protection against corrosion, both under the ceramic layer and on the roller sides. For in-line printing machines with a three-roller system we offer different geometries with screens up to 220 l/cm.

Engraving

Hexagon

Engraving

Double Cell

Product Customization

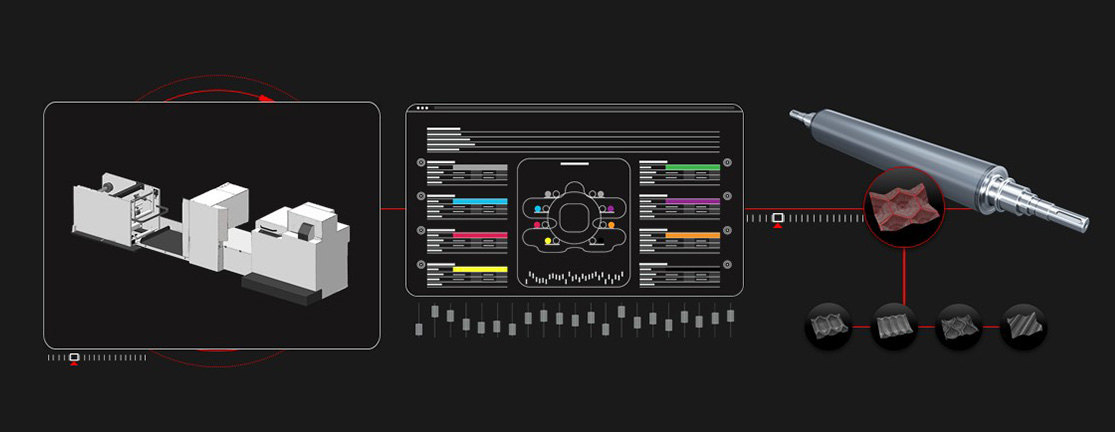

Full control of the entire production cycle as well as the technologies at our disposal allow us to identify the most suitable materials and to employ dedicated lines to respond effectively to the needs of the sector. Pre-selected, tested and validated anilox specifications for each machine model reduce the risk related to their selection. Thanks to our Simec Digital Background we ensure standardization where useful, customization when necessary, high quality and jobs repeatability.

Company

SDB

Our ERP, a tool for your business

We have transformed the traditional reactive approach into a proactive one thanks to our ability to predict our customers’ needs in qualitative and quantitative terms. We know exactly what to provide to meet a specific need and we keep stocks to ensure prompt delivery.

Purchasing Options

We rely on production lines and tools dedicated to this application. In addition to the traditional configurations, we have developed geometries that replicate those used for laser engraving into ceramics, thus optimizing the performances of each system. We detect and reproduce every geometry. The possibility of choosing among different substrates preserve the cylinders from lateral damage.

Substrates

We offer a wide range of deposition technologies, including galvanic coatings such as chrome, nickel and copper; welding coatings such as carbon-steel, stainless steel and alloys; and thermal spray coatings such as wire copper or other materials.

Purchasing Options

A coating developed to meet the needs of this industry and applied by plasma or submerged arc welding provides excellent protection against corrosion, both under the ceramic layer and on the roller sides.

Product Customization

Full control of the entire production cycle as well as the technologies at our disposal allow us to identify the most suitable materials and to employ dedicated lines to respond effectively to the sector needs. Pre-selected, tested and validated anilox specifications for each machine model reduce the risk related to their selection. Thanks to our Simec Digital Background we ensure standardization where useful, customization when necessary, high quality and jobs repeatability.

Company

SDB

Our ERP, a tool for your business

We transformed the traditional reactive approach into a proactive one thanks to our ability to predict our customers’ needs in qualitative and quantitative terms.