Nonwoven

Industries Served

Nonwoven

Industries Served

Nonwoven

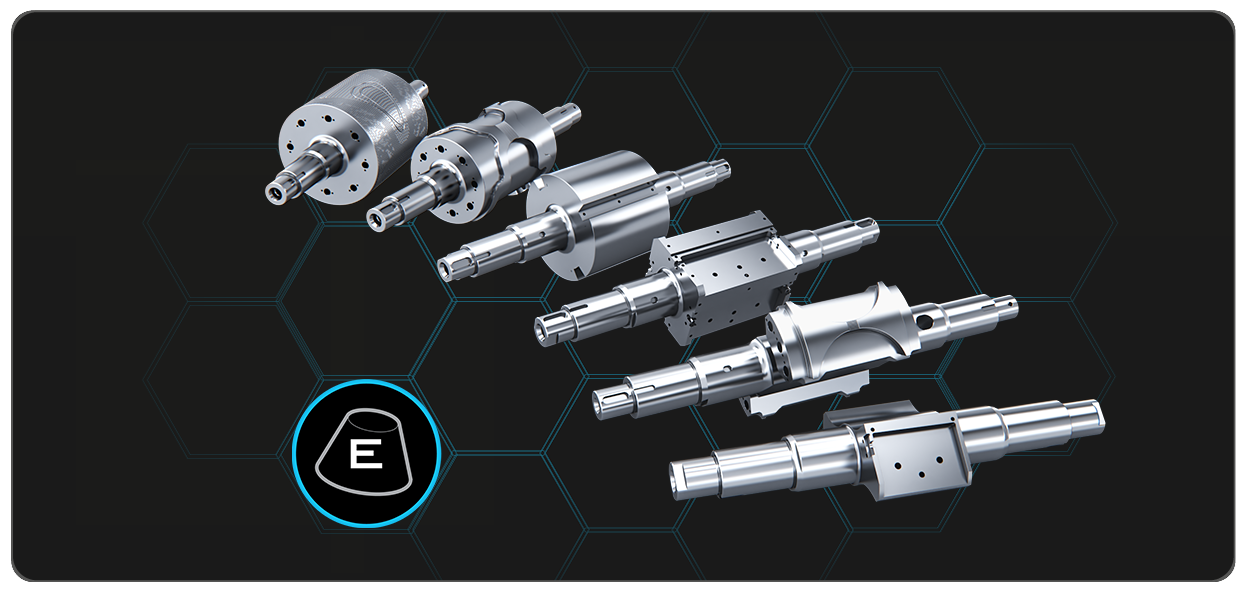

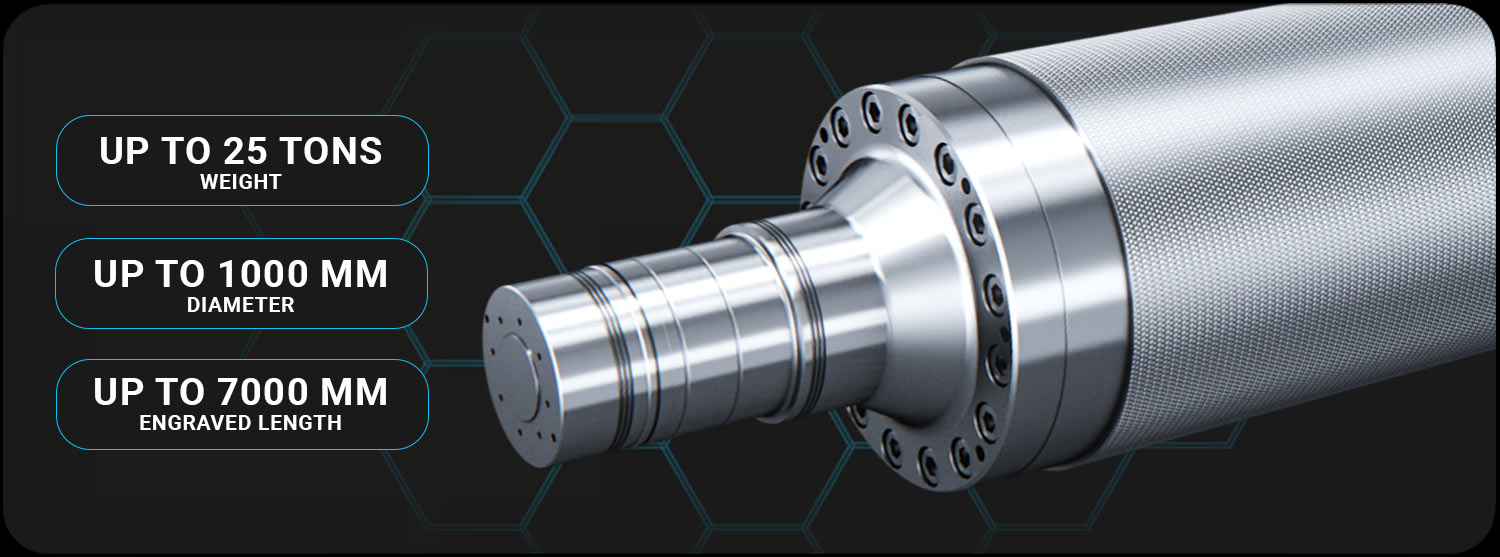

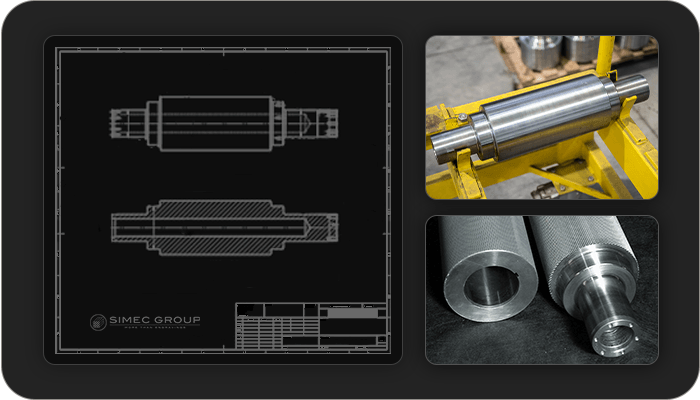

We offer rollers without size limits: weights up to 25 tons and engraved length up to 7000 mm. We carry out conventional, chemical and combined engraving, engraving both on soft and pre-hardened material. We support our customers though all steps: from the development of an idea to the after sales consultancy: pattern design, reverse engineering, vibration simulation, prototyping, calender roll engraving, coating and compaction roll engraving, kiss roll engraving, anilox for printing, drag rolls and foulards.

We offer rollers with weights up to 25 tons and engraved length up to 7000 mm. Conventional, laser, chemical and combined engraving, both on soft and pre-hardened material. Pattern development, reverse engineering, calender roll engraving, coating and compaction roll engraving, kiss roll engraving, anilox for printing, drag rolls and foulards.

Engravings

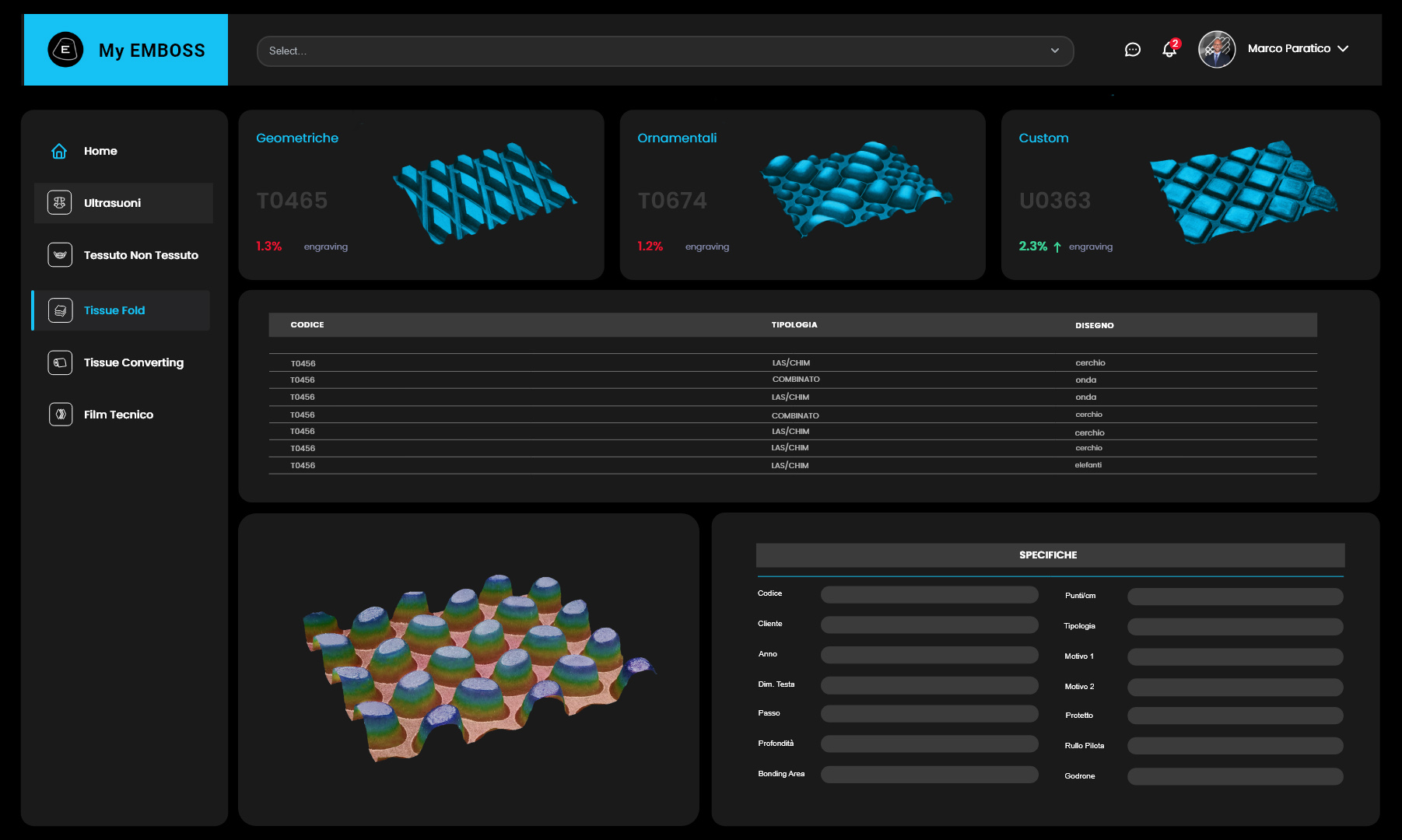

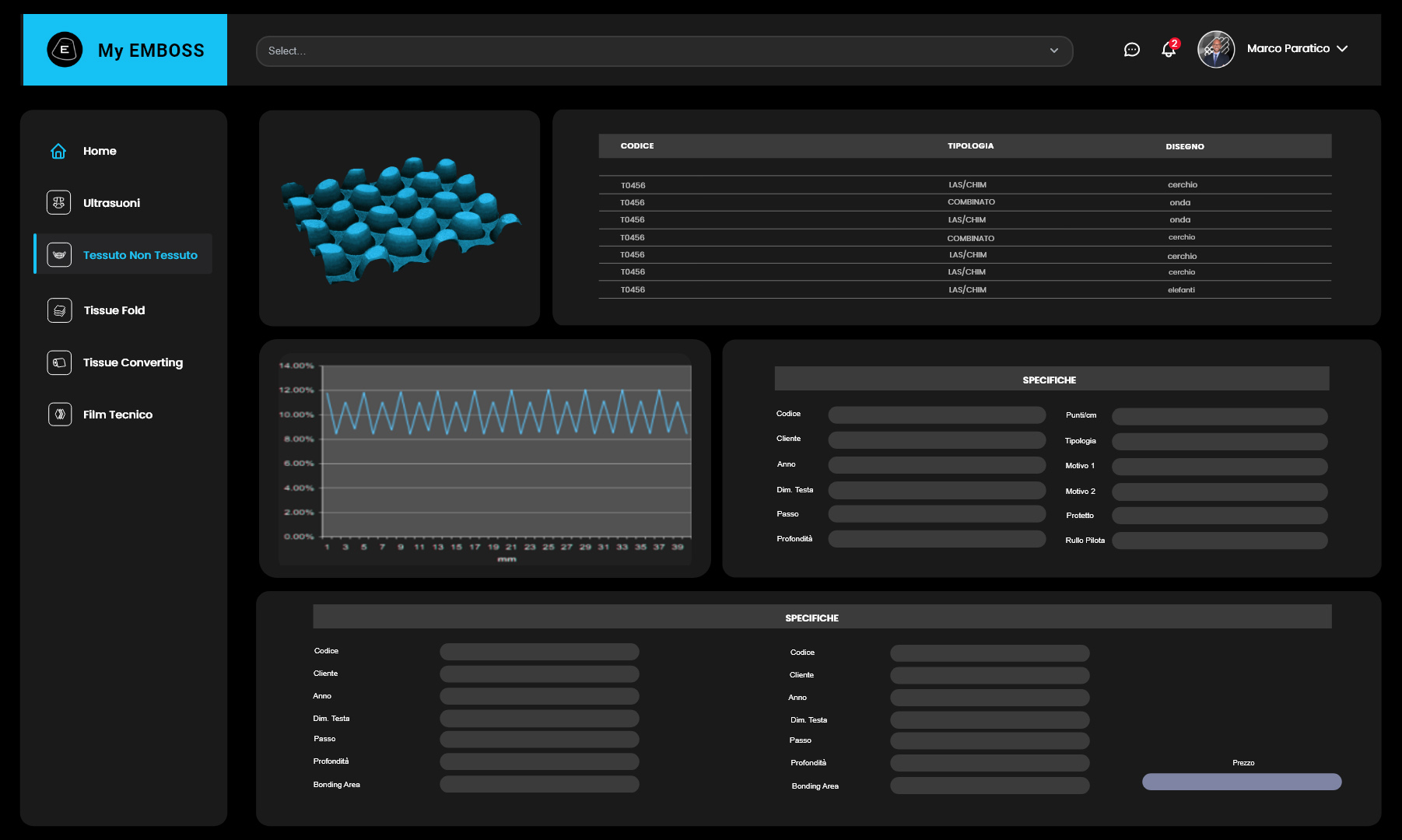

My Emboss

EMBOSS for Nonwoven

My Emboss

Cooperating remotely on technically advanced projects or defining the pattern that best serves a given purpose is not easy. That is why we have developed our MyEMBOSS, a real cylinders “personal styler”. It is a software entirely designed in-house which enable a four-handed cylinder design, browsing through a sample book of over 750 patterns. Its output can also be selected as a starting point to give life to new ideas and new ornamental models. Advice, design, just-in-time quotations: all in just a few clicks and from your own desk.

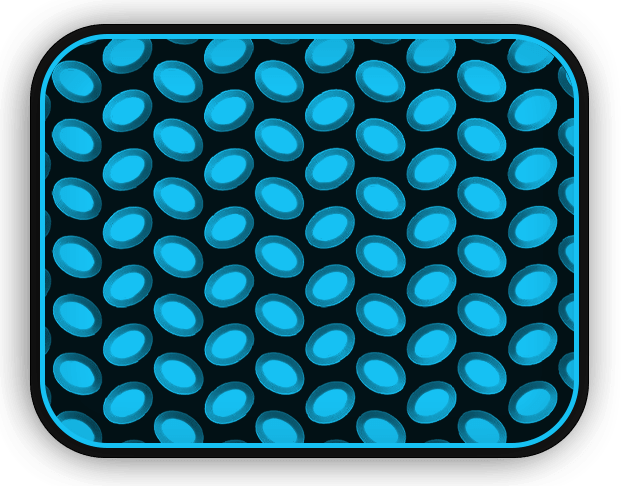

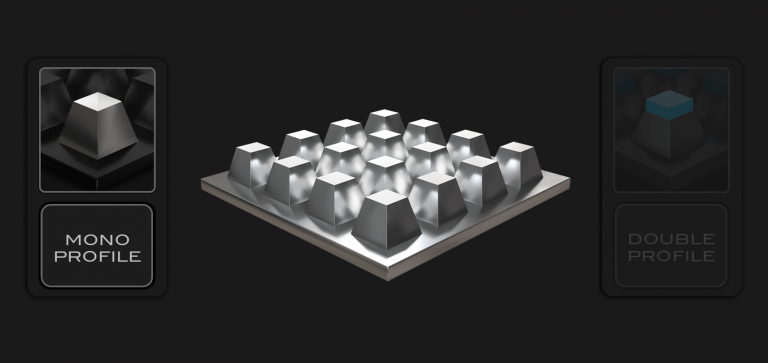

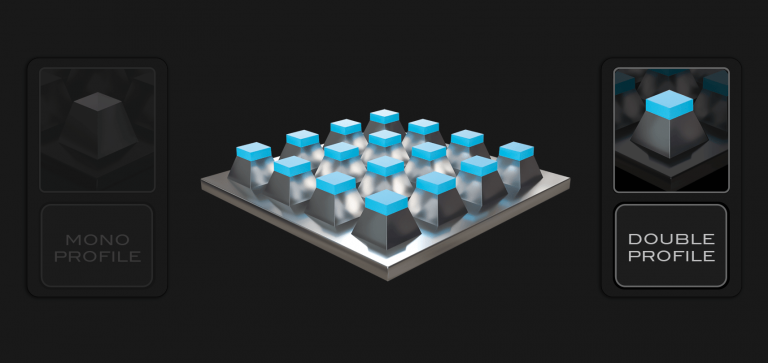

Mono & Double Profile

Double profile engraving is designed to extend the service life of the cylinder. On the other hand, the standard profile is less subjected to breakage due to the pressure exerted by the counter roller.

Mono & Double Profile

In those patterns for which double profile engraving is feasible, it lengthens the operating life of the cylinder by allowing kiss grinding without reducing the bonding percentage.

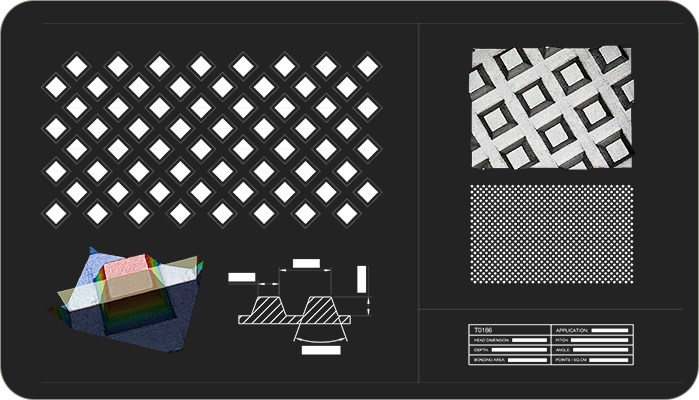

PATTERN DESIGN

Our in-depth know-how and technology allow us to develop a pattern in different ways: we take it from a sample or an existing engraving, we translate a photo or image into a drawing or we develop it by translating the customer's needs. 2D and 3D files enable us to evaluate the pins size, their concentration and the bonding area.

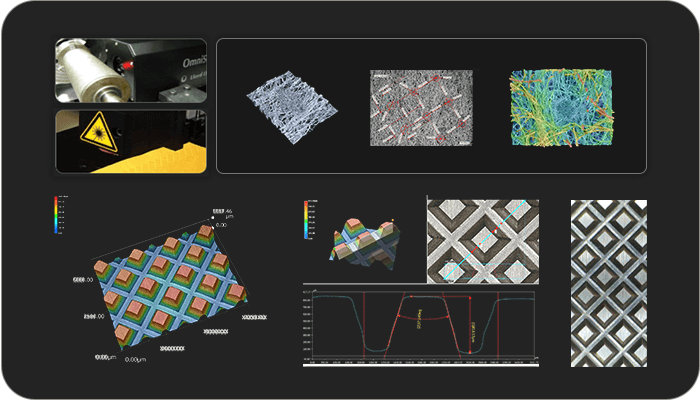

3D DETECTION

Starting from a sample or a roll we do reverse engineer. We scan any product to detect its engraving using a high-resolution electron microscope that returns a 3D image, simultaneously detecting the pattern and its different depths. We identify pin specifications and consider any possible improvement.

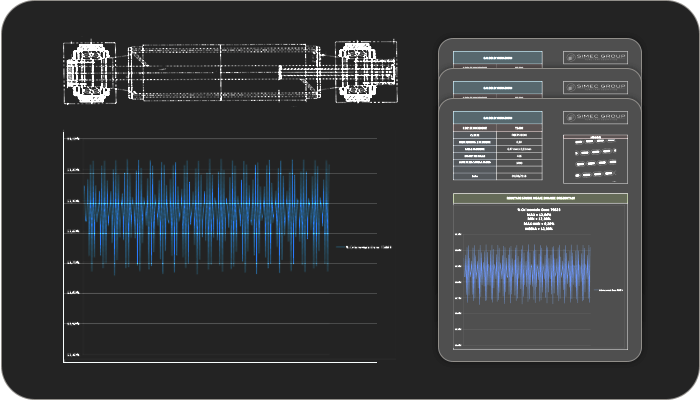

VIBRATION SIMULATION

Once a 2D engraving drawing has been obtained and rendered in 3D, we proceed to analyze it by simulating vibrations. We use a specific software capable of predicting the level of vibration of the pattern generated by the dynamic interaction between the engraved and the smooth rolls. This analysis allows us to optimize the design to reduce or eliminate the vibrations negative effect.

MACHINING STRATEGY

During the development of a new ornamental pattern it is also important to evaluate the best engraving strategy depending on the type of line, the size of the cylinder and the material to be engraved, whether soft or pre-hardened. A simulation identifies potential production problems: the choice between a mechanical, chemical, laser or combined process will also determine the costs and timing of the process.

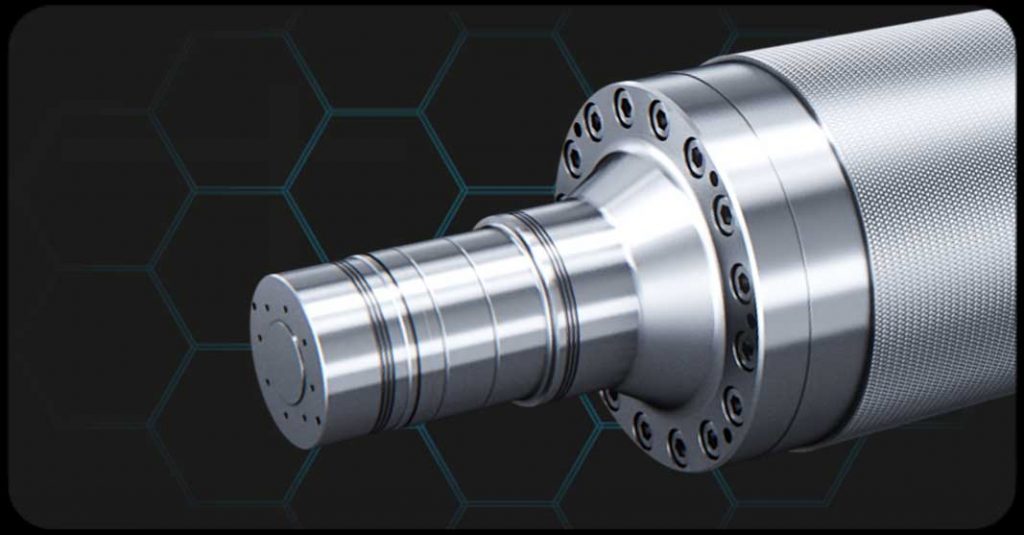

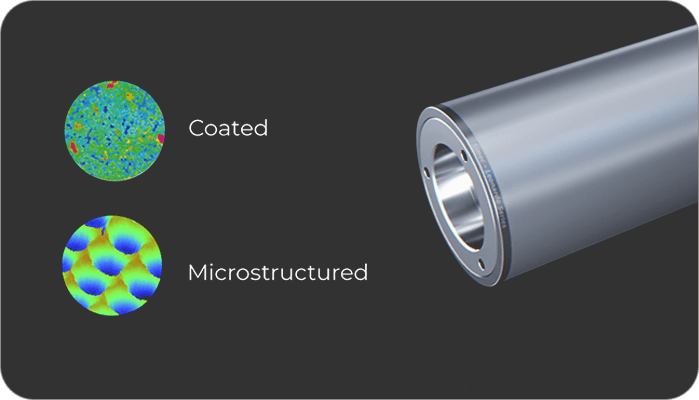

Compaction Roller

Thanks to the know-how and experience acquired in the application of coatings, we are in a position to offer compaction rollers with specific coatings or microstructures specifically conceived for Nonwoven lines. In addition to the supply of new rolls, we can refurbish rollers, bringing them back to their original conditions, working engraved length up to 5500 mm.

PROTOTYPING AND PILOT ROLLS

Once the ideal parameters have been identified and the most suitable engraving technique selected, the pattern developed can be evaluated with a 3D simulation, with an aluminum plate or by making prototypes or pilot rolls. If the resulting product meets the customer's technical and economic requirements, we go ahead with production for commercial purpose.

You might also be interested in

Ultrasonic Bonding